Scanning Offset Adjustment

Modern lasers are capable of moving very fast, and with remarkable precision, but firing the beam still takes time. Some power supplies and tubes may respond in microseconds, but others take longer. At higher speeds, belts will pull slightly as well, and all of these things can cause the output of the laser to shift slightly when engraving.

Don't forget to check for mechanical problems

Before adjusting Scanning Offset, make sure you check for mechanical problem such as loose belts which can also cause slipping and shifting.

At 100 mm/second, 254 dots per inch means your dots are 0.1 mm in length, fitting 1000 of them in 100 mm. At 100 mm/sec, if your power supply and tube take 1 millisecond to fire, your engraving will be offset by a full dot width.

At 500 mm/second, that 1 millisecond delay means you'll be off by 5 dots, or ½ a millimeter. Still not very much, but visible. Adding a bit of mechanical stretch to this will increase the offset.

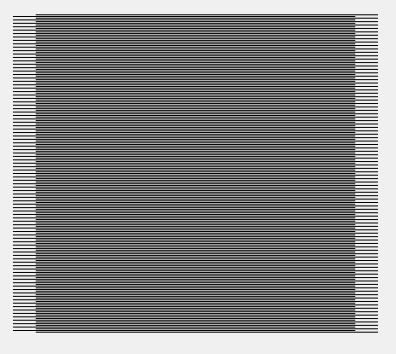

The result often looks like ghosted edges. The image below is a 20 mm square at 1000 mm/sec, with a 1ms delay, resulting in a full mm of skew between scans:

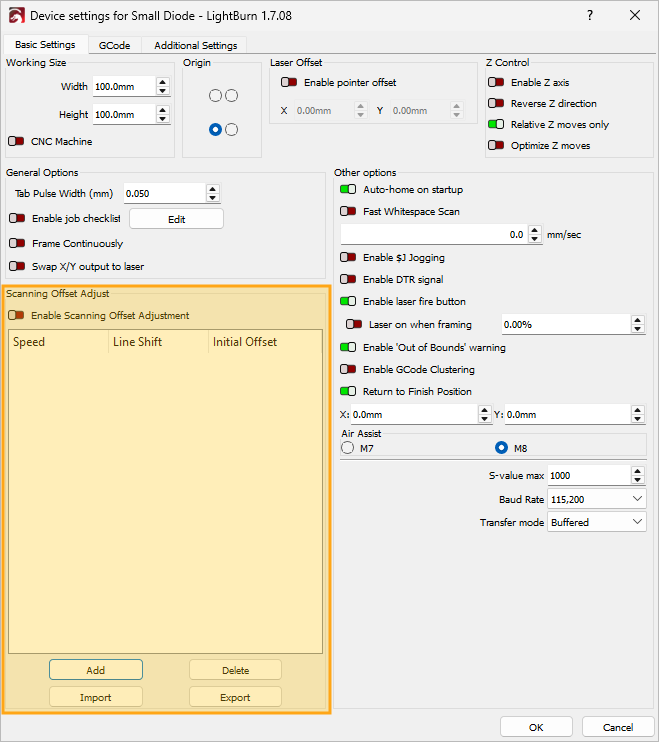

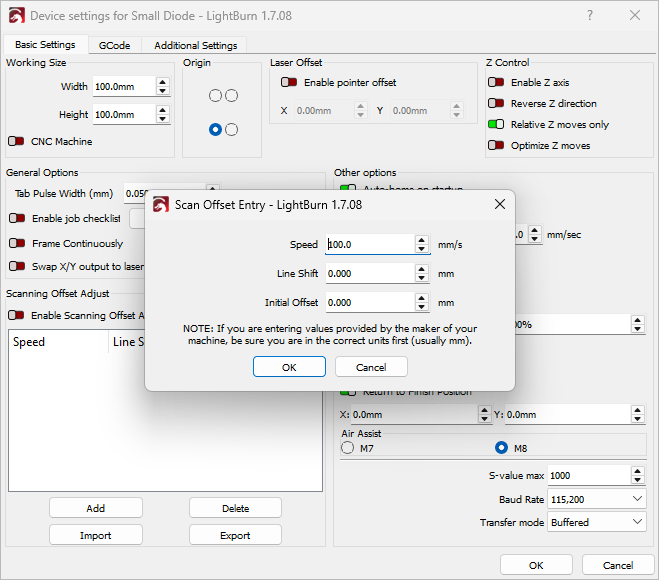

LightBurn has a setting to counter this, called Scanning Offset Adjustment, in the Basic Settings tab of Device Settings.

Note

Other software may refer to it as "Reverse Interval" or "Reverse Compensation".

Determining Scanning Offset Adjustments¶

Already have Scan Offset settings in a .lbso file?

If your laser manufacturer provided a .lbso file or you've exported your own settings, skip ahead to Importing and Exporting Scan Offset Settings.

To use this feature, you need to measure the response of your machine at a few different speeds.

-

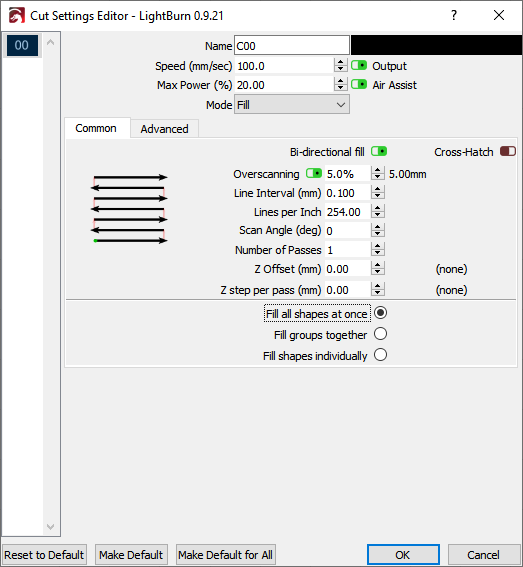

Create a rectangle in LightBurn, 50 mm wide and 10 mm high,

-

Make sure the rectangle is assigned to a layer set to Fill Mode, and apply an appropriate Power setting to visibly engrave the material you loaded into your laser without charring.

-

Set the Line Interval to 0.5 mm.

-

If you are on a GCode based device, enable Overscanning, and set it to 5% or greater to be sure the machine is not slowing down before reaching the ends. (Ruida devices overscan automatically).

-

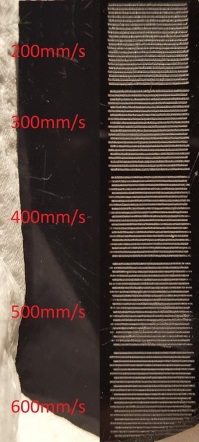

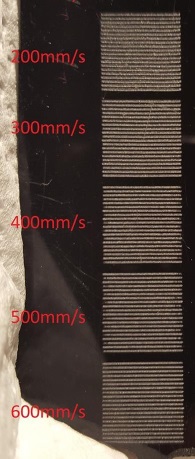

Run the rectangle at multiple Speeds. At least two will be required for this process, but using more will improve the quality of your results. Make sure you use speed settings your laser is capable of reaching, and keep track of the speed used for each run. The exact speed settings you use will depend on your machine, but you should test several different speeds representing a range of speeds your laser can achieve.

-

To compensate for the misalignment of lines, measure the distance between the ends of the lines at each Speed. You'll need to enter half that distance in the next step.

-

In the Scanning Offset Adjust section of the Device Settings window, click Add to enter the Speed and Line Shift (distance between ends of lines) values into the Scanning Ofset Adjustment table. LightBurn will use this information to compute the correct adjustments for other speeds as well.

Note

You will need to enter half the measured distance between lines — LightBurn moves each line by the amount you specify, so each pair of lines only needs to move half the distance.

-

Make sure to toggle Enable Scanning Offset Adjustment on, and click OK to exit the Device Settings window and save your changes.

-

You may need to perform this process multiple times, making minor adjustments to get clean results at each speed. After entering the measurements for the above speeds, the resulting corrected output looks like this:

Importing and Exporting Scan Offset Settings¶

Importing¶

Use the Import button in the Scanning Offset Adjustment section of Device Settings to load and apply an existing .lbso file containing Scan Offset settings. Some manufacturers provide these files to simplify the process. You can also export and import your own Scan Offset settings to move them between different computers.

Exporting¶

Use the Export button in the Scanning Offset Adjustment section of Device Settings to create a .lbso file that can later be imported on another computer to transfer Scan Offset settings.

Line Wobble¶

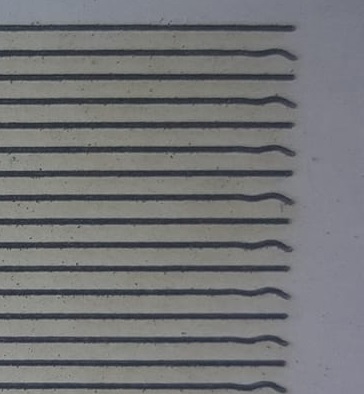

A different, but equally common problem is line wobble, often caused by too high an acceleration setting. When performing the test engraving above, you may notice lines that look like this:

If so, your machine is moving too quickly between the rows, and you're seeing physical "bounce" in the gantry because of it. Lowering the acceleration setting for your Y Axis can correct this.

Related Topics¶

For more help using LightBurn, please visit our forum to talk with LightBurn staff and users, or email support.