About Galvos¶

Note

Supported Types¶

The current types & manufacturers of galvo laser sources supported (as of LightBurn 1.2.00) are as follows:

- Raycus (RAYCUS)

- JPT (JPT)

- IPG (IPG_YLP / IPG_YLPM)

- MAX (MAX / JPT)

- CO2

- (as of 1.2.02) UV

Unsupported¶

These are devices that may work at some point in the future, have been communicated to our staff that users would like to use them, but we can't 100% confirm behavior just yet.

- QUANTEL_M20HF

- QUANTEL_M20

- MANLIGHT_PL

- VGEN_YPFL

- EO

- QUANTEL_M20EG

- QUANTEL_M30EG

- IPG_YLP_E

- HFB

- Orion Laser

Sources¶

Fiber¶

Fiber lasers are incredibly common devices, due to their use for long-distance & high bandwidth networking; fiber lasers power the internet.

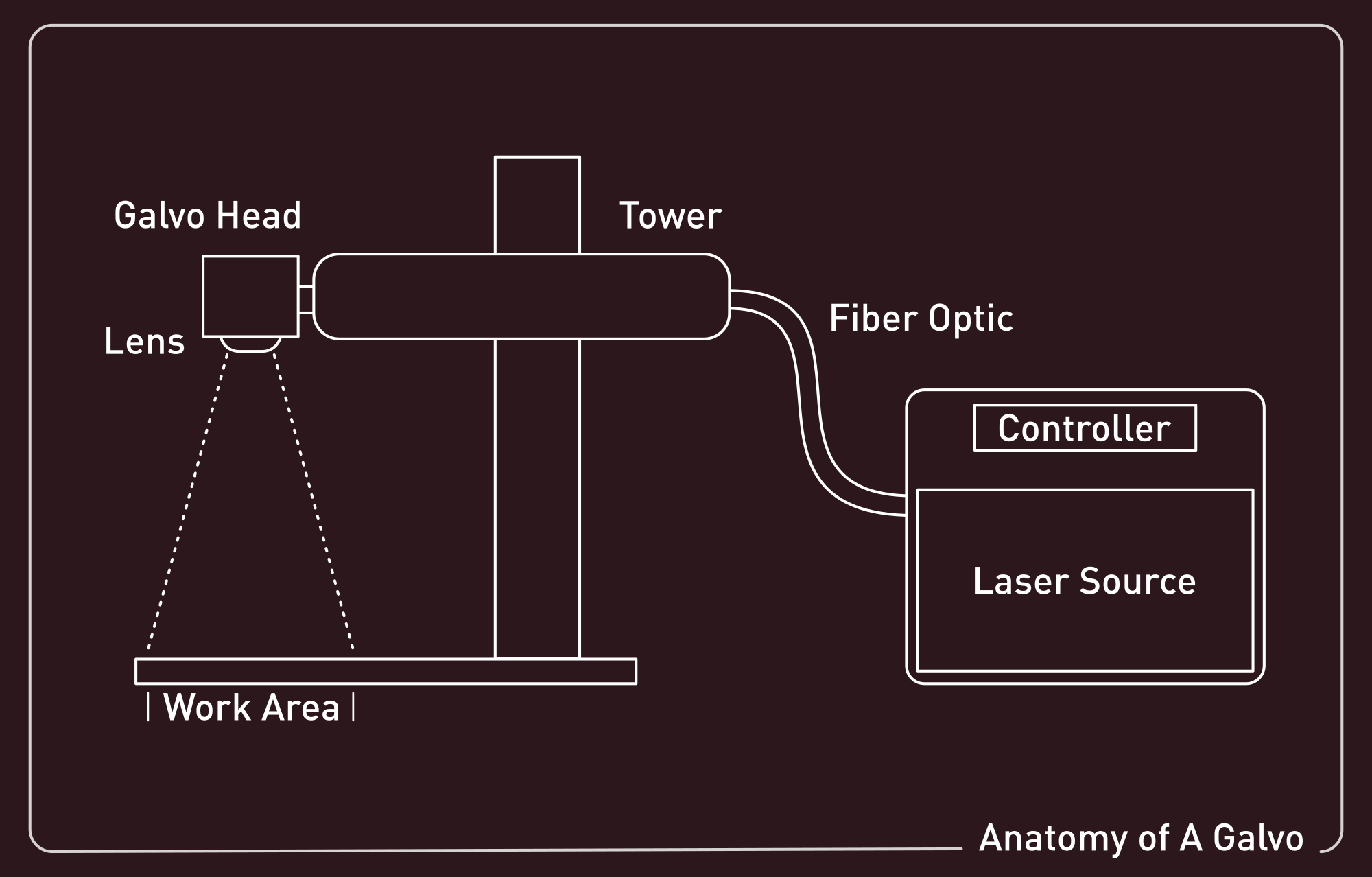

They make use of an optical pathway, made of silica glass to guide the light, resulting in a narrow, straight beam that's able to carry an incredible amount of energy and data. For galvo actuated fiber lasers, this means that the beam can move extremely quickly, making small adjustments via actuated mirrors, rather than complex gantry systems.

Due to the beam being formed inside of a solid mechanical apparatus, fiber lasers are considered "solid state" devices, whereas CO2 laser tubes are generally considered "gas state".

Step By Step¶

- Light is created in a laser diode, a dedicated source that's "pumped" into the fiber optic cable, resulting in them occasionally being referred to as a "pump source".

- Pump light is guided into the fiber optic cable. While the fiber optic is able to carry the beam, the cladding (or casing) on the fiber is the reason the beam stays inside of the fiber instead of dispersing out of it.

- Light is amplified inside the laser cavity. As the light passes through this region, the particles rise to a higher energy level, getting caught and excited / relaxed into a singular wavelength of operation. A doped portion of fiber, mixed with certain rare earth elements, makes this possible, reflecting back and forth while doing so inside "Bragg gratings". This is where it becomes a stimulated emission of radiation.

- Laser light of a particular wavelength is created. The specific element(s) used to dope the fiber effect what wavelength the beam becomes.

- The beam is released and shaped. The light at this point is collimated (straight), and to produce a usable shape for engraving, marking, or more, lenses and/or beam expanders are used to adjust the collimation.

Q-Switched vs MOPA¶

These two terms are often used in conjunction, but what does that even mean? What's being switched? Why is it a MOPA?

Master Oscillator Power Amplifier (MOPA) lasers allow more timing adjustment than Q-Switched lasers. MOPA lasers allow for separate control of pulse duration and pulse frequency to produce highly accurate and controlled engravings or etchings. The general range of MOPAs can be as low as 2ns or as high as 500ns, allowing highly accurate adjustment of the energy dispersed into the material.

Q-Switched lasers are typically not adjustable in this manner, and operate at a fixed duration, typically between 80ns to 140ns.

Laser Timing Adjustment¶

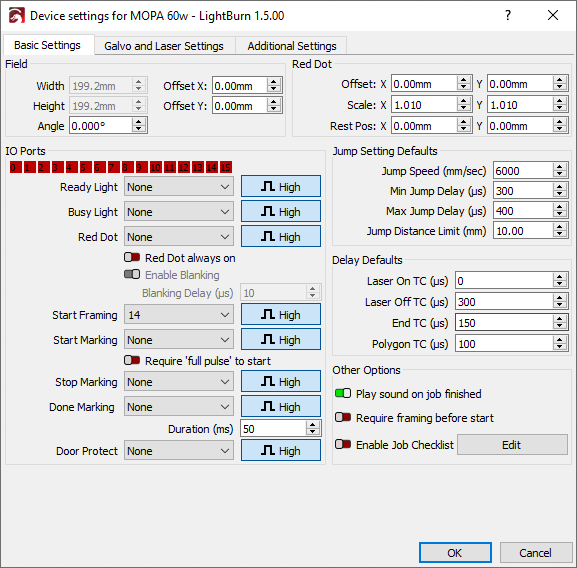

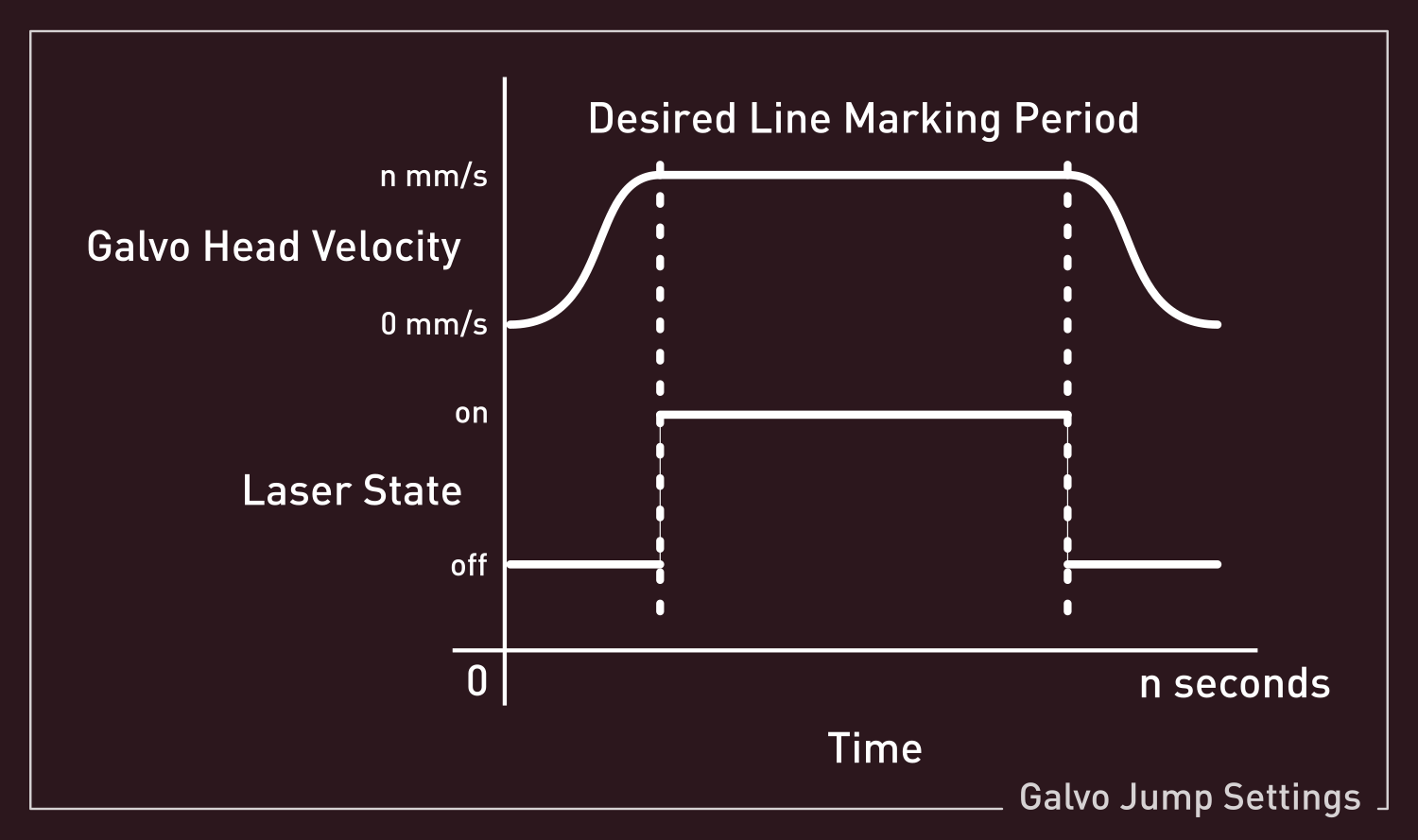

Galvo lasers sometimes have granular, but adjustable tuning of when the beam is commanded on, or off, as well as how the mirrors are adjusted. Some of this calibration and adjustment is in Lens Correction, or provided by your laser manufacturer, but the fine tuning for corner approach and speed may need adjustment.

Laser on TC (μs)¶

When attempting to mark, the physical mirrors of the galvo head must reach the desired speed before they begin marking. This fine tuning allows the user to reduce the burn-in potential during that initial acceleration by adjusting the source timing.

Laser Off TC (μs)¶

Similarly to the above, when the mirrors of the galvo head must slow down as they attempt to end a marking move, there may be a burn-in effect while slowing down. This setting allows the end timing to be adjusted finely.

End TC (μs)¶

This setting adjusts how long the laser waits at the end of a series of vectors. Due to the fact the laser will physically lag behind the commanded state as decided by any software, this delay permits adjustment similarly to the Laser Off TC, except only for the end of polygons.

This setting applies to any marking move where the laser is turned off after execution.

Polygon TC (μs)¶

This setting adjusts how long the laser "waits" at the end of each segment of a polygon, permitting the laser to settle appropriately, compensating for the same lag as outlined in End TC.