Slot & Tab Resizer¶

This feature is available in LightBurn 1.3 and higher.

About¶

Info

This is a separate tool from the tabs/bridges tool, which can be used to leave a part connected to the material it is being cut from so it doesn't fall out immediately.

Have you ever wanted to use a jointed design that was made for a different thickness of material, or wanted to cut it at a different size/scale, but the thought of manually fixing all the joints is painful?

The Resize Slots tool searches for slots or tabs of a specific size, and let you choose a new size for them to be, taking a lot of the hard work out of it!

Usage¶

This tool currently works on two main forms of geometry:

- Slots, like those found in 3D puzzles or partitions in trays, somewhat similar to a traditional halved joint or dado.

- Tabs, like a tenon or the fingers in a box joint, usually found in boxes and drawers.

Steps¶

- You'll need to know the length of the lines you want to adjust. You can use the Measurement Tool to find it if you are unsure.

- Ungroup your shapes if necessary. Then select your objects and click Tools → Resize Slots in Selection.

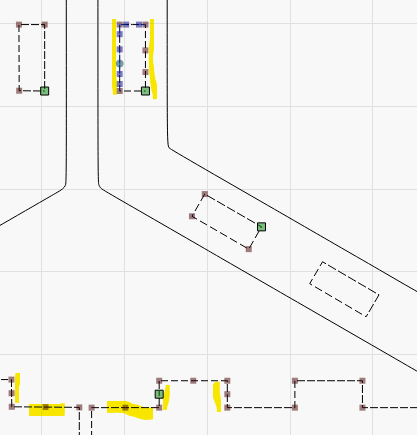

- The tool searches for tabs or slots within the selected objects, and then searches within that geometry for lines with the length you specify in Old Material Thickness. Any slots or tabs identified by the tool are highlighted in red. The lines that will move are highlighted in blue and shown with an arrow indicating the direction and distance they will move.

- Click the 'OK' button to confirm.

Settings¶

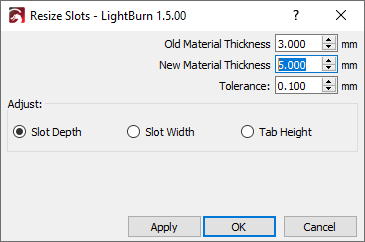

- Old Material Thickness: The current length of the lines you want to adjust.

- New Material Thickness: The length you want to adjust the lines to.

- Tolerance: Allows you to 'fuzz' the Old Material Thickness slightly. This helps if the lines vary slightly in length. It also allows you to put in the measurement of the material the part was designed for, and use the tolerance to allow for any kerf offsets built into the existing design.

- Adjust Slot Depth: Adjust the bottom/innermost line of the slot. This allows you to keep the outer size of the assembled piece the same.

- Adjust Slot Width: Adjust the sides of the slot. This would typically be used when the slots are meant to intersect on the interior of a laser cut piece instead of on the corners, like boxes.py's tray insert

- Adjust Tab Height: Adjust the top/outermost line of the tab. This allows you to keep the interior size of the assembled piece the same, while making it bigger or smaller on the outside.

Troubleshooting¶

- The tool doesn't yet work on internal slots/ cutouts/ mortises as it's tricky for the computer to determine which direction they should grow/shrink.

- The tool searches ungrouped objects. If it's not recognizing the tabs or slots in your design, try ungrouping your objects.

- The tool only works on sharp (not filleted/rounded) corners. Some tools (like boxes.py) default to adding small loops on internal corners and small filets/rounded corners on external ones. The external filets ones can be removed using the Radius Tool and the internal loops can be removed using the Offset tool set to 0.

- The tool requires well-formed shapes as an input. If the shape has extra nodes, or if any of the lines are technically curves (even if they're straight), it will interfere with slot/tab detection. The highlighted sections in the image below show examples of problematic shapes. You can use optimize selected shapes to try to repair these shapes.