Rotary Setup (DSP)¶

Info

This will walk you through setting up and using your rotary attachment with LightBurn for gantry (non galvo) lasers. To set up a rotary with a galvo laser, please see Rotaries for Galvo Lasers.

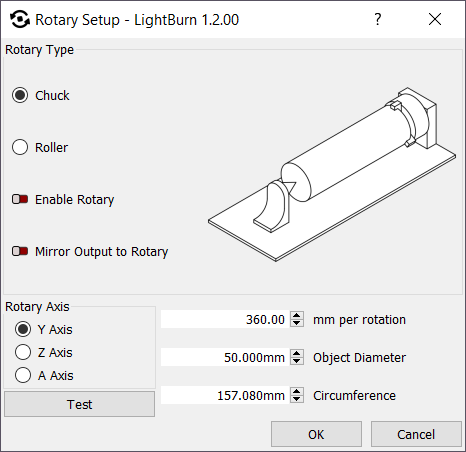

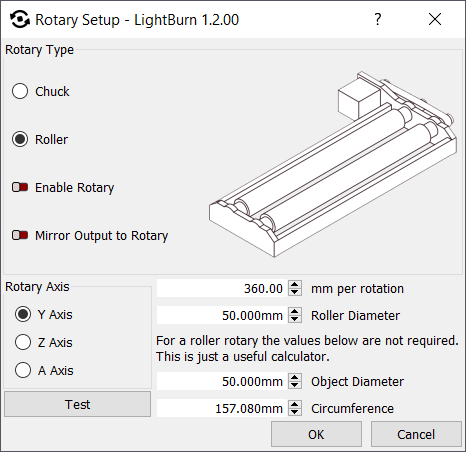

In the top menu bar, click the Laser Tools menu (or just Tools in older versions of LightBurn), then Rotary Setup, and it will open the rotary setup window, shown here:

Rotary Setup¶

The window may look different depending on the type of controller you have, and in fact, you may not be able to access this menu item at all - most Trocen controllers, for example, require setting rotary parameters through a menu on the controller panel itself.

General Rotary¶

- Choose whether you have a chuck style or roller attachment.

- Click the enable rotary check box (it will turn green when enabled).

- In the steps per revolution box, enter the number of steps it takes your attachment to make one full revolution. For a chuck rotary, this will be one rotation of the chuck, and for a roller, it will be one full rotation of the roller, NOT the item. For GCode devices with a dedicated rotary axis, this number should just be "360 degrees". If not using a dedicated rotary axis, you'll have to use trial and error to dial in the correct travel distance using the Test button.

- Click the Test button to verify that the roller or chuck makes one full rotation, pauses, then returns.

-

Enter either the diameter of the object to be engraved or it's circumference, the other value will be automatically calculated.

-

Align your object under the laser head in a position where the X axis will start and rotate the object in the rotary attachment to the point where you want the Y axis to start engraving.

- When using the rotary, it's generally a good idea to use "current position" as the "Start From" setting.

- Click Start to run your job, or if you have a DSP controller, you can use Send to send it to the controller to run it from there.

- Remember to uncheck the use rotary attachment check box once you are finished so that you do not impact your next regular project.

Notes¶

-

If the object slips on the rollers of a roller type attachment, wrap the rollers with some sort of non-slip material or even rubber bands.

-

You can also try placing some weights inside the object such as ball bearings or other small round objects, this will help press the object against the rollers.

-

If you end up with a flat part at the 'bottom' of the engraving, it means your rotary gear mechanism has backlash. In general, tightening any belts in the rotary device will fix this, but if not, you can place a small line a few mm below the bottom of your design, set to very low power, like 0.1%, and set it as the first layer to run. The rotary will spin to this position, then back up over that few millimeters of gap, and will take up the backlash with that movement.

DSP Specific Setup¶

If using a Ruida controller, disconnect the Y axis stepper connection and connect the rotary attachment to the Y axis. If using Smoothie or GRBL, C3D, or Smoothieware controllers, click the "A" axis selection. (See below on how to configure your controller steps before you proceed).

Note

If you are using a DSP controller (Ruida, etc), when you change the rotary setting you need to power-cycle the controller, as the internal logic isn't adjusted for the rotary setting unless you do this. Change the setting, close the Rotary Setup window to write the change to the controller, then power off the control board and power it back on. You will likely need to press the Esc (or stop) button on the controller to prevent it from trying to home itself, as the Y axis will not home properly.